Pwm Specifications

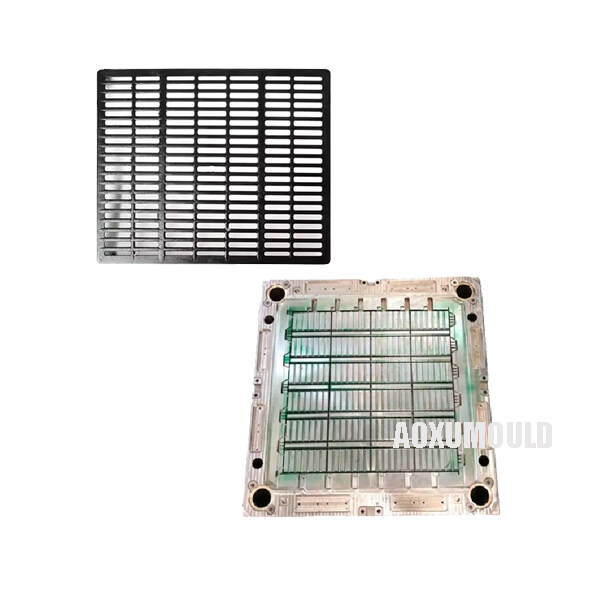

|

Pwm npe |

Cage Mat Pwm |

|

Cov khoom siv |

PP / HDPE, yas |

|

Khoom Loj |

340 x 250 x 10 mm |

|

Khoom hnyav |

1, 28 kg |

|

Pwm khoom rau kab noj hniav &. Core |

C45, P20, 718, 2738 |

|

Pwm puag |

P20 |

|

Txhaj tshuaj |

Txias / Kub khiav |

|

Tsim nyog txhaj tshuab |

380T |

|

Pwm loj |

580x5200x430mm |

|

Pwm lub neej |

ntau tshaj 500,000pcs |

Cage Mat Mould yog dab tsi?

Yas tawb lev pwm yog hom pwm siv los tsim lub tawb mats ua los ntawm cov yas. Cov mats no feem ntau yog siv rau hauv cov nqaij qaib ua liaj ua teb, ua liaj ua teb nrog cov tsiaj nyeg, thiab cov chaw nyob tsiaj los muab qhov chaw xis nyob thiab huv si rau tsiaj.

Cov yas txhaj tshuaj tawb lev pwm feem ntau yog ua los ntawm cov hlau zoo thiab tsim los tsim cov lev nrog ntau qhov ntau thiab tsawg thiab cov qauv. Cov txheej txheem molding yuav tsum melting yas resins thiab txhaj cov khoom molten rau hauv pwm kab noj hniav nyob rau hauv siab. Tom qab txias, lub lev raug tshem tawm ntawm cov pwm, ua rau cov khoom siv tau ntev thiab ntev tuaj yeem tiv taus kev siv hnyav.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm cov yas txhaj tshuaj pwm pwm yog lawv lub peev xwm los tsim cov mats nrog cov khoom zoo sib xws thiab siab precision. Qhov no txhais tau hais tias cov mats uas tsim tawm yog cov tuab tuab thiab kev ntxhib los mos, uas ua kom cov tsiaj nyiam thiab nyab xeeb thaum so ntawm lawv.

Lwm qhov kom zoo dua ntawm cov yas txhaj tshuaj tawb lev pwm yog lawv cov kav ntev. Lawv tuaj yeem tiv taus rov siv dua thiab tiv taus kev puas tsuaj los ntawm cov tshuaj lom neeg, raug tshav ntuj, thiab kub heev. Qhov no ua rau lawv muaj txiaj ntsig zoo rau cov neeg ua liaj ua teb tsiaj thiab cov tswv tsev uas xav tau hloov lawv cov ntaub pua tsev tsawg dua.

Nyob rau hauv xaus, yas txhaj tshuaj tawb lev pwm yog ib tug tseem ceeb cov cuab yeej rau ua tau zoo mats siv nyob rau hauv cov tsiaj ua liaj ua teb thiab chaw vaj tse. Lawv muaj ntau yam zoo, xws li kev sib xws, durability, thiab nqi-zoo, uas ua rau lawv nyiam cov neeg ua liaj ua teb thiab cov tswv tsev.

Cov khoom siv yas twg yog siv los tsim Cage Mats?

Cage mats feem ntau yog siv nyob rau hauv cov chaw nyob tsiaj thiab chaw kho tsiaj los pab muab qhov chaw xis nyob thiab nyab xeeb rau tsiaj. Lawv yog ib qho tseem ceeb rau kev saib xyuas kev nyiam huv hauv cov tsiaj nyob hauv tsev vim nws pab tiv thaiv cov khoom pov tseg, av, thiab kab mob. Ib qho khoom siv nrov siv los tsim lub tawb mats yog yas.

Yas yog cov khoom siv dav siv rau ntau lub hom phiaj vim nws muaj ntau yam zoo. Nws yog lub teeb yuag, yooj yim los ntxuav, tsis ntxeem tau, thiab tiv taus cov kab mob loj hlob. Cov khoom zoo no ua rau nws yog cov khoom siv zoo tshaj plaws rau kev tsim cov khoom siv ruaj khov thiab tu cev.

Polypropylene thiab polyethylene yog hom yas siv los ua lub tawb nqa khoom. Polypropylene yog ib hom polymer uas feem ntau siv los tsim cov khoom sib txawv xws li ntim, textiles, thiab lev. Nws yog kub-resistant, hloov tau, thiab muaj zog. Polyethylene yog lwm hom yas uas siv dav los tsim ntau yam khoom. Nws yog lub npe hu rau nws yooj, lub teeb-yuag thiab durability.

Ob leeg ntawm cov yas no muaj kev nyab xeeb, tsis muaj tshuaj lom, thiab tsis tso cov tshuaj phem, ua rau lawv muaj kev nyab xeeb rau tsiaj siv. Cov ntaub ntawv no kuj tuaj yeem tiv taus kev tu thiab ua kom tsis muaj menyuam, ua kom yooj yim rau kev tswj xyuas ib puag ncig huv rau tsiaj.

Hauv kev xaus, cov ntaub ntawv yas yog qhov kev xaiv zoo tshaj plaws rau kev tsim lub tawb mats vim lawv cov durability, huv si, thiab ntau yam. Nrog kev tu thiab tu kom zoo, cov ntaub pua plag yas tuaj yeem muab qhov chaw nyob ntev thiab xis nyob rau ntau yam tsiaj tuaj.

Yuav Ua Li Cas Tswj Xyuas Qhov Zoo ntawm Yas Cage Mat Pwm?

1. Siv cov khoom siv zoo

Qhov zoo ntawm cov khoom siv yas siv hauv kev txhaj tshuaj pwm yog qhov tseem ceeb hauv kev txiav txim siab qhov khoom kawg ntawm kev ua haujlwm ntev thiab kev ua haujlwm. Siv cov ntaub ntawv zoo raw khoom guarantees cov khoom kawg yog muaj zog, resilient, thiab ntev-ntev, thaum cov ntaub ntawv qis dua yuav ua rau puas thiab tawg. Yog li ntawd, nws yog ib qho tseem ceeb rau cov khoom zoo tshaj plaws los ntawm cov neeg muag khoom txhim khu kev qha kom ntseeg tau tias cov khoom lag luam zoo tag nrho.

2. Xyuas kom tsim nyog txhaj tshuaj pwm tsim

Ua ntej pib txheej txheem txhaj tshuaj molding, nws yog ib qho tseem ceeb kom paub meej tias cov pwm tsim nyog rau cov khoom npaj. Kev tsim pwm yuav tsum ua kom haum txhua yam khoom tshwj xeeb thiab tsim kom muaj qhov loj me los tsim cov khoom zoo. Muaj cov pwm tsim tau zoo yog qhov tseem ceeb hauv kev tiv thaiv qhov tsis xws luag hauv cov khoom tiav.

3. Saib xyuas cov txheej txheem ntau lawm

Nws yog ib qho tseem ceeb los saib xyuas thiab tswj cov txheej txheem tsim khoom kom ntseeg tau tias cov khoom tsim tau ua raws li cov qauv tsim nyog. Qhov no yog ua los ntawm kev tshuaj xyuas tsis tu ncua ntawm cov pwm thiab cov khoom tsim, nrog rau kev saib xyuas cov txheej txheem tsis xws li kub, siab, thiab lub sijhawm voj voog. Los ntawm kev ua tib zoo saib xyuas cov txheej txheem tsim khoom, txhua qhov teeb meem tuaj yeem txheeb xyuas thiab kho sai, ua rau cov khoom zoo dua qub.

4. Kev nqis peev rau niaj hnub txhaj tshuaj molding tshuab

Niaj hnub nimno txhaj tshuaj molding tshuab muaj cov yam ntxwv siab heev uas pab tsim cov khoom zoo. Cov kev nce qib no suav nrog cov tshuab automation, kev saib xyuas lub sijhawm tiag tiag, thiab cov txheej txheem kev tswj hwm qib siab. Kev nqis peev nyob rau hauv niaj hnub txhaj tshuaj molding tshuab tsis tsuas yog lav cov khoom sib xws tab sis kuj txo cov sij hawm tsim khoom thiab cov nqi.

Hauv kev xaus, kev tswj thiab tswj qhov zoo ntawm cov yas tawb lev txhaj pwm yuav tsum muaj kev mob siab rau txhawm rau txheeb xyuas qhov tsis xws luag thaum ntxov hauv kev tsim khoom thiab saib xyuas cov txheej txheem tsim khoom kom zoo. Siv cov khoom zoo raw khoom, xyuas kom tsim pwm tsim, saib xyuas cov txheej txheem tsim khoom, thiab kev nqis peev hauv kev txhaj tshuaj molding tshuab niaj hnub yog txhua yam tseem ceeb ntawm kev tsim cov khoom zoo.

Tsim Rau Khoom &. Pwm

Pob &. Kev xa khoom

Pwm Cheebtsam

Pwm Hlau

Kub khiav System

Standard Parts

FAQ

Vim Li Cas Xaiv Peb

1. Kev paub: Peb lub tuam txhab tau nyob hauv kev lag luam rau ntau xyoo thiab muaj kev nplua nuj nyob hauv cov txheej txheem yas txhaj tshuaj molding. Peb pab pawg kws tshaj lij tau ua haujlwm nrog ntau tus neeg siv khoom thiab cov haujlwm, muab lawv cov kev paub thiab kev txawj ntse los muab cov kev pabcuam zoo.

2. Zoo: Peb txaus siab rau peb txoj haujlwm zoo thiab xyuas kom txhua yam khoom peb tsim tau raws li cov qauv siab tshaj plaws. Peb tsuas yog siv cov ntaub ntawv zoo tshaj plaws thiab cov thev naus laus zis tshiab los xyuas kom meej tias peb cov khoom muaj kev ntseeg siab thiab ruaj khov.

3. Kev Pabcuam Cov Neeg Siv Khoom: Peb pab pawg kws tshaj lij tau mob siab rau muab kev pabcuam tshwjxeeb rau cov neeg siv khoom. Peb ua haujlwm ze nrog peb cov neeg siv khoom kom nkag siab txog lawv cov kev xav tau thiab xyuas kom meej tias peb xa cov khoom raws li lawv qhov kev cia siab.

4. Tus nqi sib tw: Peb muab cov nqi sib tw yam tsis muaj kev cuam tshuam rau qhov zoo. Peb lub hom phiaj yog los muab peb cov neeg siv khoom zoo tshaj plaws rau lawv cov nyiaj.

5. Innovation: Peb tau cog lus tias yuav nyob twj ywm nrog cov thev naus laus zis tshiab thiab cov qauv tshiab hauv kev lag luam. Peb pheej nqis peev rau hauv cov cuab yeej tshiab thiab software los xyuas kom meej tias peb muab kev pabcuam zoo tshaj plaws rau peb cov neeg siv khoom.

Zuag qhia tag nrho, peb lub tuam txhab yas txhaj tshuaj pwm yog qhov kev xaiv zoo tshaj plaws rau txhua tus neeg uas tab tom nrhiav kev txhim khu kev qha, zoo, thiab pheej yig yas txhaj tshuaj molding kev pabcuam. Tsis txhob yig tiv tauj peb hnub no kom paub ntau ntxiv txog qhov peb tuaj yeem ua rau koj!

Cov neeg siv khoom tawm tswv yim